Home » Pallet Packaging » NanoWrap

Introducing NanoWrap, a revolutionary stretch wrap for cost-effective, wrap-efficient packaging.

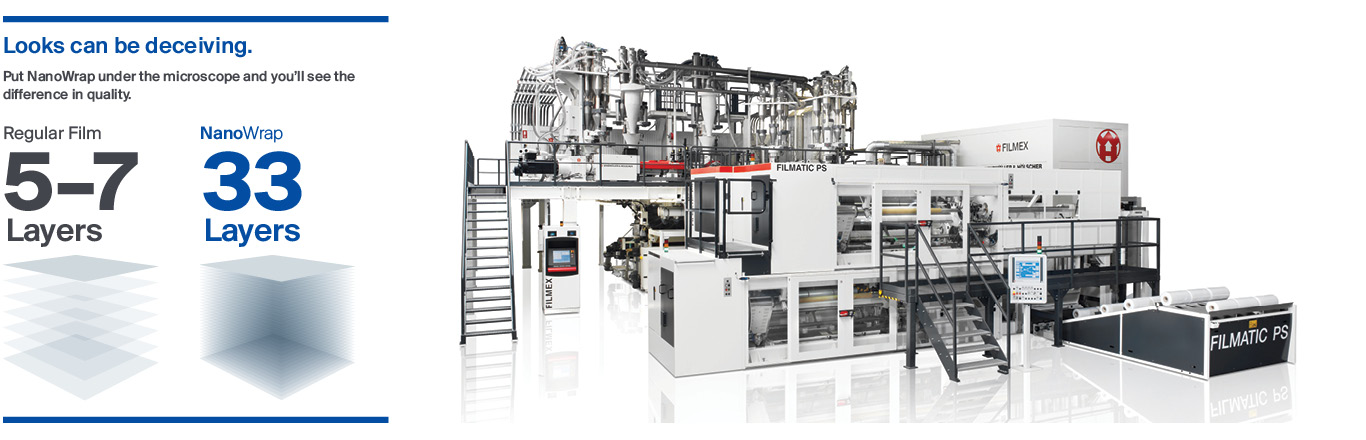

We are proud to offer this high-tech future-focused pallet wrap to forward-thinking companies around New Zealand. NanoWrap is the result of a big investment in research and development – joining multiple layers into an ultra-thin polymer required specialist expertise and technology. The result was worth it. 33 layers of high-performance wrap – a uniquely formulated film with a core formation to deliver 300% stretch capacity and maximum load stability, minimal weight and enduring peace of mind.

The success of NanoWrap© has not come overnight. Years of diligent research and development were undertaken before it was time for the first roll out of the wrap.

The primary focus of the R&D stage was on increasing structural strength and extension without compromising durability or increasing wastage. Successfully joining multiple layers into an ultra-thin polymer required the introduction of specialist technology and equipment.

The result was 33 layers of high-performance raw material – a uniquely formulated film with a core formation delivering maximum load stability and stretch capacity with minimal weight.

It’s how NanoWrap© now provides far greater benefits compared to conventional 5-7 layer stretch films. It’s why attention to the small details delivered big innovation for our wrap – and huge strength to your packaging.

With 33 layers of specially formulated films NanoWrap delivers unrivalled performance levels in load distribution and production resistance. Even though overall thickness is reduced (in comparison to other packaging films) load stability is far higher.

Achieving the perfect balance between ‘better safe than sorry’ wastage and ‘we thought it was safe, we’re sorry’ breakage can be difficult. With NanoWrap you’ll have ultimate peace of mind that your pallet is packaged and protected.

The toughness test.

The ASTM D1709, ISO 7765-1 standards use the Dart Puncture Impact test to determine the impact strength and/or toughness of plastic film. This test uses a single dart configuration and a single drop height, while varying the weight of the dart.

When compared with conventional film NanoWrap displayed significantly higher resistance to punctures.

The best way to ensure a cost-efficient introduction of any new wrap product is with an initial SCOPE consultation from our technical sales team.

With this expert evaluation you’ll receive all the relevant figures and the best way forward before any trial is undertaken.

From there you’ll see the difference in costs for yourself – we have achieved proven savings of over 35% when NanoWrap has been introduced.

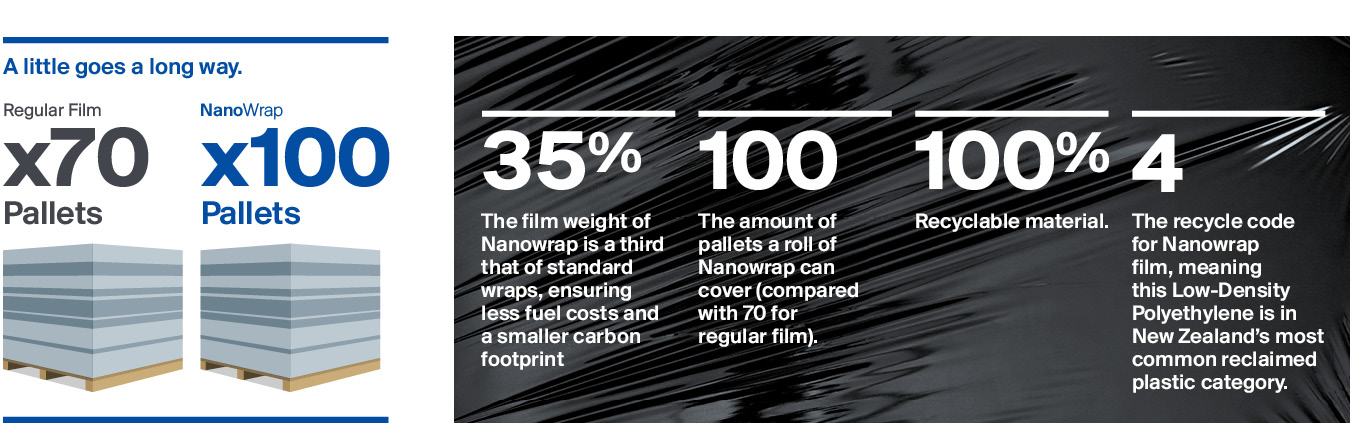

Our responsibility to sustainability must therefore always concentrate on how we can do more with less. It’s why we’re so proud of the gains that NanoWrap has made.

NanoWrap can reduce film weight by a staggering 35%.

Yes, that’s right. The fully recyclable plastic wrap delivers the exact same load coverage and containment as that of twice as much conventional wrap.

This unique capability massively reduces film waste and subsequently minimises any potential landfill impact too.

There’s also a reduction on shipping weight – with less weight per pallet less fuel is needed. So you can reduce your carbon footprint by ensuring fewer resources are used with less waste as a result.

From sugar to cleaning products to baby food, leading New Zealand companies have already discovered the difference NanoWrap can make to their bottom line. Are you ready to make the move?

NanoWrap© has already improved the overall film load containment and reduced the per-pallet cost for companies like NZ Sugar, Nutricia and 30 Seconds.

When it comes to meeting and surpassing everyday packaging standards NanoWrap ticks every box as easily as it covers

every pallet.

To receive a free audit today with one of our technical sales team contact our service team on 0800 700 000.

| 20412 – Nanowrap 12 | Uploads/Datasheets/20412_NanoWrap12_Datasheet.pdf |

| 20415 – Nanowrap 15 | Uploads/Datasheets/20415_NanoUV_Data-Sheet.pdf |

| 20417 – Nanowrap 17 | Uploads/Datasheets/20417_NanoWrap17_Datasheet.pdf |

| 20420 – Nanowrap 20 | Uploads/Datasheets/20420_NanoWrap20_Datasheet.pdf |

| 20415UV – Nanowrap 15 UV | Uploads/Datasheets/20415UV_NanoUV_Data-Sheet.pdf |

Load protection. NanoWrap delivers unrivalled performance levels in load containment and puncture resistance. Even though the overall thickness is reduced (in comparison to other packaging films) load stability is far higher.

Eco sustainability Reduce film weight by 35% and massively reduce waste and minimise potential landfill impact. With less shipping weight less fuel is needed too, making NanoWrap a win-win choice.

NanoWrap is 100% recyclable. It is classified as Code 4 LLDPE plastic which is fully recyclable within the NZ Waste & Recycling system.

Cost Savings. The smallest gains can make a big difference in logistical costs. So when 1 metre of un-stretched Nano film is stretched to 4m of wrap, you’re using up to 35% less product per pallet, well… those savings can be significant.

| Code | Description | Rolls Per Carton | Rolls Per Pallet |

|---|---|---|---|

| 20412 | NanoWrap Machine Stretch Wrap, 500mm x 2720m x 12um | 1 | 50 |

| 20415 | NanoWrap Machine Stretch Wrap, 500mm x 2175m x 15um | 1 | 50 |

| 20416 | NanoWrap Machine Stretch Wrap UVA, 500mm x 2175m x 15um | 1 | 50 |

| 20417 | NanoWrap Machine Stretch Wrap, 500mm x 1920m x 17um | 1 | 50 |

| 20420 | NanoWrap Machine Stretch Wrap, 500mm x 1630m x 20um | 1 | 50 |

| 20477 | NanoWrap Machine Stretch Wrap, 750mm x 1920m x 17um | 1 | 30 |

| 20480 | NanoWrap Machine Stretch Wrap, 750mm x 1630m x 20um | 1 | 30 |