Sustainability

How we can help you cut plastic waste and prevent product damage...

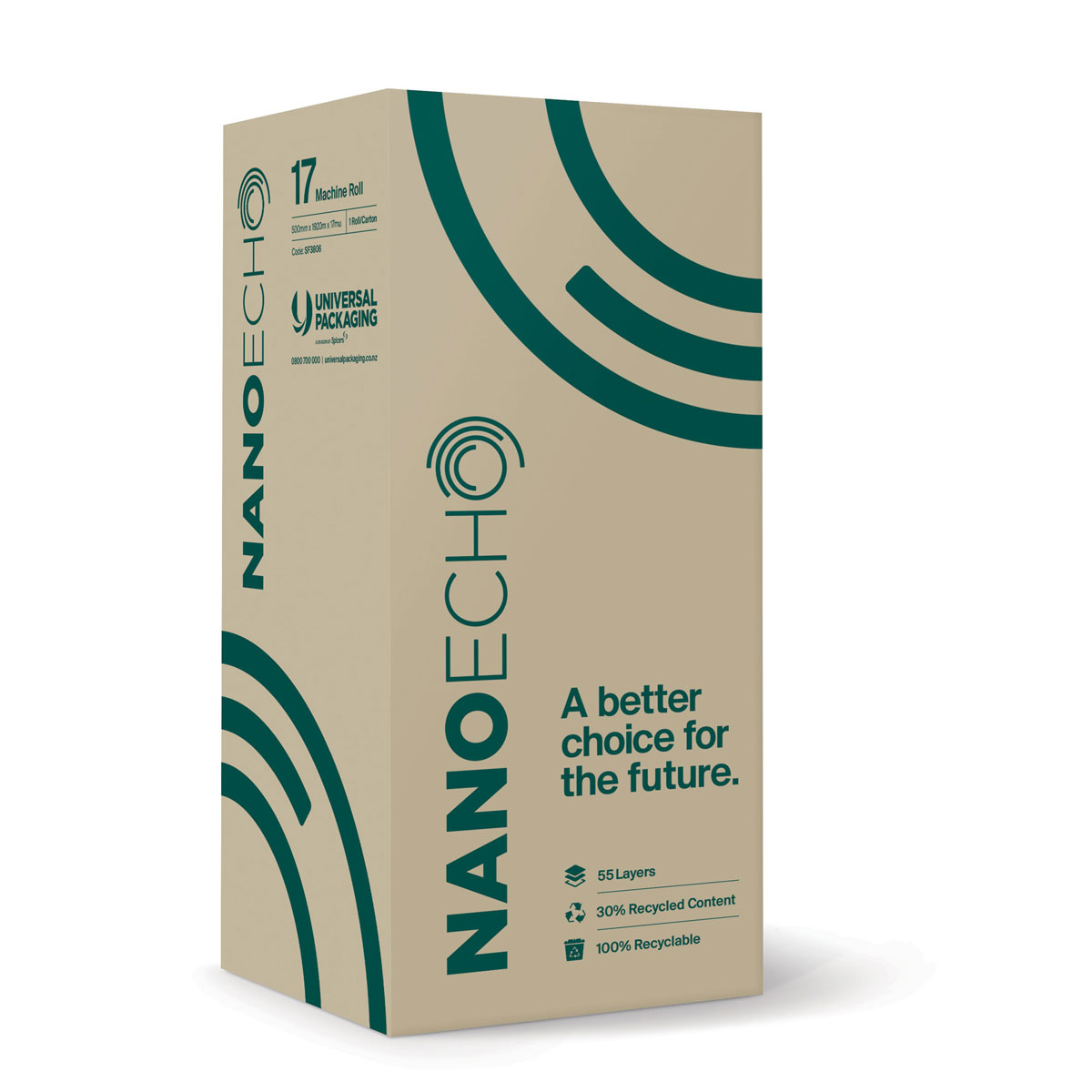

Resounding change: NanoEcho

A helping hand: Recycling right

We champion the work done by Pioneer Group to ensure New Zealand businesses have a quick, easy way to recycle used wrap. Their plastic compactors lead the market, helping businesses reduce paper, plastic, and other waste volume by up to 90%.

Big picture vision: Containment testing

Future focus: Research and development

We partner with leading international researchers and manufacturers that work with innovation and passion to deliver positive change. This is why our range leads the way in wrap integrity and waste minimisation, with products like NanoEcho, NanoWrap and XTWrap delivering more packaging strength with less wrap.

FAQs

We work with Pioneer Group. Their plastic compactors are easy to install and use. From there you can use a number of local providers to collect and dispose of your plastic waste.

Trials are underway currently with a paper-based pallet wrap. While commercial viability is still some time away, we expect this to eventually be a viable alternative to current pallet wrap.

Currently some 480,000 tonnes of paper fibre are collected annually across New Zealand, around 50% of which is recycled here. The remainder has been exported but overseas demand has reduced considerably for mixed papers. Domestic fibre processing is at full capacity however, and it will take significant capital investment to increase this capacity.

We look forward to this occurring. While we will certainly be early adopters of this packaging, a holistic and pragmatic view must be taken to ensure of the best possible result.

Simple answer: No. Stretch wrap that contain prodegradant additives such as oxo-degradable and photo-degradable plastics contain additives that makes them break down faster. Unfortunately, this type of wrap quickly fragments into smaller pieces, known as microplastics.

Oxo-degradable and photodegradable plastics cannot be composted or recycled and are another source of contamination for NZ’s recycling system – making environmental problems worse. The government announced in June 2021 that NZ will be phasing out oxo and photo-degradable plastics by late 2022.

Yes, because in our work ‘less’ can be ‘more’. More companies using our services to wrap less means our reputation as an industry leader continues.

That’s why there are no ‘more or less’ measurements at Universal Packaging. We calculate everything to ensure your packaging can protect your goods and prevent damage without using unnecessary resources. Our aim is to save you plastic with each and every pallet.

No, 33 and 55 layers does not increase the density of the film. There are instead more layers of high performance ultra-thin material within the specified micron of the film. This enables this pallet wrap to stretch further while staying stronger than other film.

Get in touch today to have one of our expert technical sales team help you optimise your wrapping processes and minimise your packaging waste.

Plastic identifications codes are used to separate the different types of plastic material, PET, LDPE, PVC for example. Code 4 plastics are packaging materials made from low-density polyethylene resin. These are one of the most common types of plastic packaging in New Zealand.

As stretch wrap is generally not printed and is clean it is easier to recycle than plastic that has been contaminated with food or heavily printed with ink. For more information we suggest visiting the Plastics NZ website.

The 55-layer NanoEcho stretch film is made from 30% recycled material, allowing it to stretch further and wrap with strength without relying on nearly as much traditional plastic material. Large distributers make significant carbon reduction gains by using this innovative pallet wrap.

Our expert team at Universal Packaging can assess your machinery and make recommendations for what will work best.

Biodegradable plastics are plastics that can be completely broken down via natural processes. This can take up to 100 years to occur.

Oxo or Oxy-biodegradable plastics have an additive that speeds up this process of degradation. However, as it does not occur naturally, micro particles can still be detected, particles that will linger in the earth’s environment for much, much longer.

Bio-based plastics are primarily made from bio-materials and renewable raw materials such as cane sugar. These plastics can be fully recycled in standard recycling systems.

Presently there are no biodegradable or compostable wrap solutions available that perform as well as standard LLDPE film. While there are some options in the marketplace, testing shows that these don’t meet the performance criteria we require for our clients. Which means less strength in wrapping and more potential product damage – a result that’s counterproductive for all.

In New Zealand waste disposal systems also aren’t set up to accept these kinds of films efficiently. Compostable film cannot be mixed into the normal recycling streams and if disposed of in landfill it offers little environmental benefit than standard stretch film. Until a commercial composting facility can handle the capacity in New Zealand we do not recommend using this film.

If your business will only be wrapping product that is used in a closed-loop operation (meaning there are arrangements with a commercial compost facility and there is control of all wrap disposal post-use), then biodegradable or compostable wrap may be viable. If your operation could benefit from this, please get in touch and we can discuss your options.

First, get a good packaging audit from an industry specialist. With the advice and expertise of our team we can run your pallets through a number of focused testing processes. In doing so we’ll be able to accurately gauge what is going where and how improvements can be made. These are often small tweaks that can have big consequences on the plastic used.

Often we’ll suggest moving from older, traditional stretch film packaging to new Nano film packaging.

NanoWrap helped lead the way here. This innovative nano-layer cast film allows our customers to save up to 50% in wrap use (and the associated cost savings that come with this change).

Now NanoEcho is providing even more savings – this 55-layer sustainable pallet film is made from 30% recycled material and fully recyclable.

Overall, it pays to have a pragmatic look at the bigger picture around your wrapping processes. We help with technological advice, layout changes and other key facets of the distribution model, ensuring everything is as efficient as possible.

Let’s be honest – many might think a company in the plastic industry has no business highlighting sustainability issues. The reality is that we work with raw material that is harmful to the environment when not used correctly and recycled properly.

However, it’s very clear that stretch film is still the best way of preventing damage to goods in transit. Without it, there would be much more waste. It is necessary – but so too is our responsibility to limit its use.

We continue to strengthen our efforts to ensure our products are used in the most sustainable way possible. Not only are we helping to dramatically reduce waste; we’re also actively developing new solutions for a far more sustainable future. The continued good health of our local, national, and global environment is crucial to this future. We want the next generation to inherit a world we are proud of.

Being sustainable

is valuable

Less waste means less costs, in every sense of the word. Moving from inefficient pallet film to new can save up to 50g on ever pallet wrapped. If you’re wrapping 100 pallets a day that’s the annual equivalent of:

Being sustainable

is purposeful

There are big, bold initiatives and smaller everyday measures to reduce a carbon footprint. We always look to do both. With changes in product and process the technology is now available to ensure a huge difference in waste in the years to come with some companies aiming for a:

Being sustainable

is achievable

The tools with which to achieve real lasting change are available right here, right now. For preventing product damage using the least amount of plastic there is one leading choice. NanoEcho’s 55-layer film provides strength and integrity in wrap while being made from: