Site optimisation

Unwieldy layouts and ineffective planning can often compromise the valuable real estate within a distribution centre. These inefficient, labour-intensive wrap processes inflate costs and increase the potential for product damage.

Space and time are a key focus for our consultant team during their work auditing and advancing layout efficiency within any distribution centre operation. This expert analysis ensures companies can make the most of each moment – and more from every movement.

When it comes to site layout, small moments (such as when a forklift stops to wait for a wrap to be completed) can have a large cost in terms of time, fuel, and frustration. Optimising the location of different elements on site can eliminate or greatly reduce these moments – while increasing team safety and reducing product damage.

The Universal Packaging consultant team provides regular guidance around New Zealand. Distribution centre layout is often a combination of common sense and expert insight. We ensure our customers have the confidence they have the right equipment, in the right place, with the right amount of people for the necessary throughput.

Download the brochure

Download the PDF FAQs

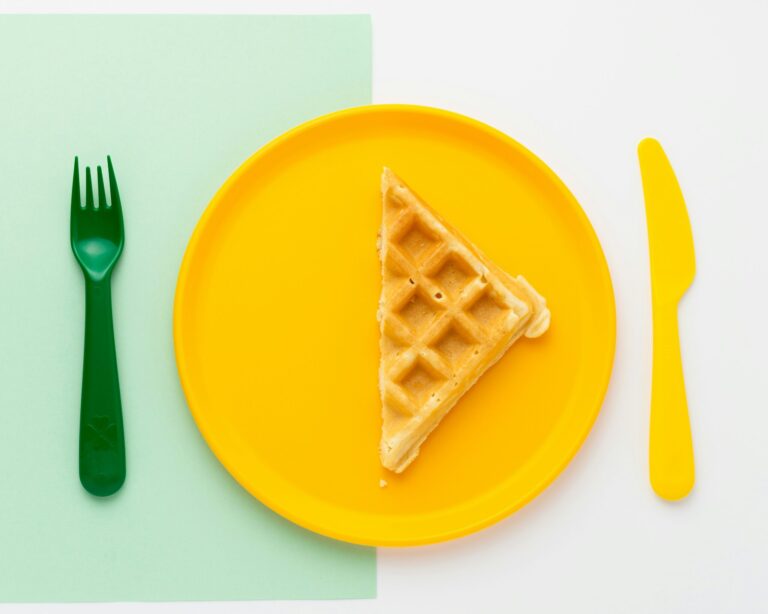

Think of it like cooking, where the ‘kitchen triangle’ is used by designers for optimal efficiency. By positioning the stove, sink and bench in a triangular arrangement there are no steps wasted for the home cook. A distribution centre is similar – just on a much larger scale. Any layout should allow for safe and smooth movement of goods without time and energy ebbing away.

With less time taken in moving goods around the distribution centre, staff time can be used in other areas of the business.

With less travel required from MHE operators, companies can achieve greater efficiencies in fuel use and reduce equipment replacement costs. With these changes to a set-up, centimetres of change can result in kilometres of savings.

When considering your layout and the machinery required, it’s imperative to consider the function and needs of your centre. A production centre or manufacturing plant will be better suited to a conveyorised wrapping system, while a traditional large distribution centre will generally operate more efficiently with a drive-through set up.

We can provide an ROI calculation for your site, showing how time, labour and energy can be maximised with either a new layout and/or an investment in new equipment. With the data in place, it should be clear whether part or full automation is required.

Increasing efficiency (and therefore sustainability) will generally come down to a combination of the right wrap and the right equipment. Changes to either should be backed up by solid figures, which is why getting a site optimisation analysis done is so important.

To ensure any disruptions have minimal effect on business any changes are best made in off peak times.

No posts found