Breadcrumb section

Measure up

Be it packaging, equipment, or other processes, our constant refrain when it comes to suggesting new approaches is “if we can’t measure it, we won’t recommend it”. As companies make moves to cut costs and stay competitive in these challenging times it’s this approach that our customers are appreciating more and more.

Universal Packaging can ensure quick, quantifiable gains and long-term peace of mind thanks to the cutting-edge testing equipment we’ve invested in.

With these systems, we can quickly and accurately measure the pallet film’s containment force and puncture resistance on any load, anywhere. This means that no change is arbitrary – and every improvement is backed by reliable data.

Close enough is not good enough

When dealing with major quantities of any product there can be huge gains made from changes in pallet film or wrapping equipment.

For larger operations that can mean saving approximately thirty to fifty cents in wrap and labour per pallet with the move into greater automation of pallet wrapping. While thirty cents may not seem like a lot with the amount of throughput such operations can see thousands of dollars in savings per day.

We cannot afford to get such figures wrong when making such proposals. In New Zealand’s comparatively small market word travels fast. Our reputation is too precious to squander on a single instance of careless analysis or deceptive advice. That’s why we undertake a rigorous testing process – one that’s easily scalable to all sizes of business.

A trusted partnership

Universal Packaging partners with Highlight Industries for all of our stretch film testing equipment requirements.

The U.S company is proud of their reputation for producing the most technically advanced stretch film testing equipment in the world. They’re widely recognised as leading the way by which quality control is delivered to stretch film and resin producers.

In April 2015 Jed Goudie and Matt Goddin travelled to Grand Rapids, Ohio to visit Highlight’s head office for comprehensive product training. Since then we’ve met regularly with them to keep up to date with all the developments in both stretch film application and new innovation in field-testing technologies.

The right tools for the task

We use Highlight’s Portable Film Force System. This is the newest and most accurate way to measure and record the containment force and puncture resistance of stretch film when on site around New Zealand.

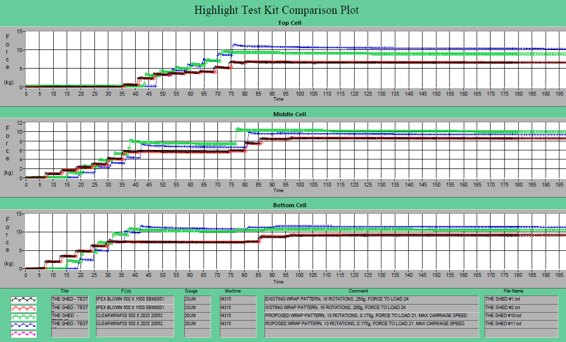

The system is a powerful tool for understanding how existing products are wrapped. The information we receive from the PFFS allows us to understand wrapping operations with greater insight, to establish key benchmarks and to then make changes make changes, compare results, reduce costs and improve overall wrapping performance.

What we offer

With the PFFS we can arrive on site and quickly get to work assessing and testing pallet wrap. The process can be expanded with additional load cells to suit any load profile and the counterweight-and-strap system allows easy testing on any load.

The system records and displays test data to our laptop directly, allowing us to collect, record and graph data instantly in real time and then compare multiple tests in seconds.