S300 Pallet Wrapping Machine

For pallet packaging that requires a little more muscle, the Spinny S300 is ready to do the heavy lifting. With a power carriage that can pre-stretch wrap by up to 300% you’ll get firmly wrapped pallets with a lot less film.

This power in freight packaging capability saves most operators between 40% – 50% in film costs, meaning the S300 provides a healthy ROI for larger-scale distribution centres that already do a lot of wrapping.

This pallet wrapping equipment reduces plastic use with a combination of strength and flexibility. As opposed to a conventional application system, machine-tensioned film allows light or unsteady loads to be wrapped securely and consistently. Operators with diverse wrapping requirements can conveniently program up to ten wrap cycles to cater for all load possibilities. Sound like something that will spin your wheels? Then get in touch with our expert team today.

Ideal for

- High volume distribution centres

- Optimising inventory management

- Wrapping very light, very heavy or unstable pallets

- Unpredictable pallet loads

- Powered pre-stretch film carriage – 200%

- Quality equipment made in Italy

- 3 year factory warranty

- Soft start and stop turntable function

- Indexed turntable returns to start

- Photo cell for automatic load height detection

- Touch screen control panel giving 5 programmable wrapping options

- Touch screen control panel offers ability to lock programs to stop operator interference

- Single phase

- Full service maintenance plans

- Parts backup

- Excellent after sales support and operator training

- Turn table diameter up to 2200 mm

- Wrap height up to 3800 mm

- Loading ramp

- Integrated load cell and weight indicator

- Pit frame

- With slotted turntable for pallet trolley

| Turntable table diameter | 1650 mm |

| Turntable capacity | 2000 kg |

| Distance between mast and turntable | 500 mm |

| Wrap height | 2100 mm |

| Turntable Speed | 0 to 16 rpm |

| Production Rate Per hour | 25-35 loads |

| Power Supply | Single Phase |

Related news

02 April, 2025

Ready for the revolution? Get onboard with the S140

The S140’s capabilities make it the perfect ‘Goldilocks’ choice for those wanting to send pallets sustainably,...

18 May, 2023

At your service: What’s the best pallet wrapper for your DC?

How do you choose a pallet wrapping machine that perfectly fits the unique needs of your distribution...

20 February, 2023

Spin Zone

The S140’s capabilities make it the perfect ‘Goldilocks’ choice for many New Zealand companies who want...

16 November, 2022

Case Study: Seales Winslow

The adjustable tension during the cycle is a massive help compared to what we had (pre-fire). There’s...

10 November, 2022

Case Study: Sanitarium

Some things in life just go together perfectly. At Sanitarium that’s obviously Weetbix and fruit, Light...

05 October, 2022

A load off your mind

The growth in popularity of the Spinny S300 will come as no surprise to those who have worked with this...

18 August, 2022

Get with the program

Once you have your programmed settings in and become familiar with the control panel, the Spinny S140...

07 June, 2022

Elevation from semi-automation

With the ongoing challenges of a wobbly workforce many Kiwi companies are doing it tough trying to effectively...

27 April, 2022

At your service

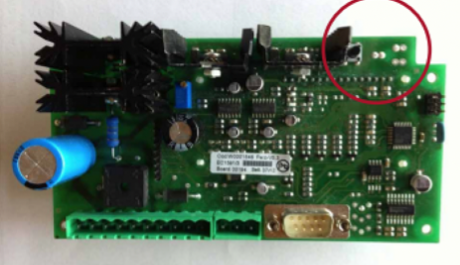

It’s time to say arrivederci to frustrating language barriers on your Spinny machine.