Just the highlights

NanoWrap proved that sustainable pallet wrapping can make a major difference and now NanoEcho is helping NZ companies take the next big step. However, when it comes to enacting real positive change and exceeding sustainability targets, it’s still important that solutions are made to measure.

Your New Year’s equipment resolutions

The new year is always a good time to take a realistic look at what you aim to achieve and to start in with some good habits to make these goals a reality.

Forking out for a new machine

Our old electric forklift has been basically driven into the grave.

Maintenance issues

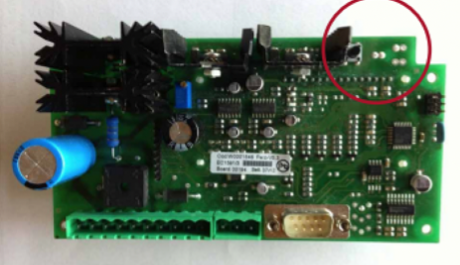

Regular maintenance on pallet wrappers is necessary to ensure a healthy return on investment on the equipment.

A load off your mind

The growth in popularity of the Spinny S300 will come as no surprise to those who have worked with this powerful, adaptable stretch wrapping equipment.

Elevation from semi-automation

With the ongoing challenges of a wobbly workforce many Kiwi companies are doing it tough trying to effectively and quickly palletise and ship goods. Now more than ever it seems easier to hand over your pallet shipping protection to semi-automation. And there are plenty of ways to make the right move in a financially prudent manner too…

At your service

Your pallet wrapper is a valuable member of the warehouse team and, when it goes down, so does the chances of winning the DC game. It’s best to avoid injury to the wrapper in the first place – which is why we recommend the following “prehabilitation” strategies…

Doing it right

While Bunnings customers might visit to get their DIY fix, it’s not a desirable approach for their distribution centre.

At your service

It’s time to say arrivederci to frustrating language barriers on your Spinny machine.

Roll call!

Just like loading a roll of toilet paper onto the holder, there’s a right way and a wrong way to reload your Wulftec stretch wrapper.